How to Fix Drain Stopper in Sink: A DIY Guide

Learn a clear, step-by-step approach to fix a stuck or leaking sink stopper. Tools, troubleshooting, and maintenance tips from Drain Guide to restore a smooth drain and prevent future clogs.

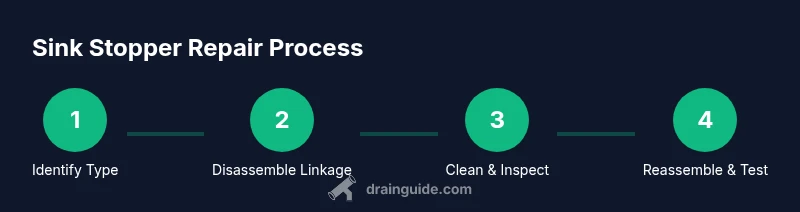

In this guide, you’ll fix a stuck or slow drain stopper in a sink using common tools and safe steps. You’ll identify stopper type, disassemble carefully, clean debris, reassemble, and test for proper sealing. No plumbing license required; this DIY approach suits most standard bathroom and kitchen sinks. Follow along for photos and diagrams to guide every step.

How a Sink Stopper Works and Why It Fails

A sink stopper is the small mechanism that seals the drain when you close the sink, and it can affect flow and odors if it fails. In most homes, a stopper is connected to a lift rod or a pivot rod under the sink, and a washer or seal keeps water from draining when closed. When hair, soap scum, mineral buildup, or misalignment push debris into the seal, the stopper may stick, sit too high or not seal completely.

According to Drain Guide, the most common failures are hair and soap scum collecting around the stopper, a loose linkage that allows wobble, or a worn washer that keeps water from sealing. Recognizing which failure is happening is key before you disassemble. Visual checks: is the stopper moving freely? Does water drain slowly even when you push or pull? Do you notice leaking around the drain before you run water? These signs guide your approach without overhauling the whole assembly.

Next, understand the difference between the main stopper types. Lift-and-turn stoppers spin to lock and unlock; pop-up stoppers use a central post and horizontal linkage; toe-tap stoppers react to a light tap to close or open; and plunger stoppers rely on a push-pull action. Each type has its own service points and potential wear areas. Knowing the type helps you prepare the correct tools and step-by-step actions.

Common Stopper Types and What to Look For

Stopper mechanisms vary by design, but the goal is the same: create a water-tight seal when closed and allow free drainage when opened. Lift-and-turn stoppers usually require a small rotation to free the seal; pop-up stoppers rely on a vertical rod and pivot; toe-tap stoppers respond to a light tap to operate; and plunger stoppers are pushed in and pulled out to seal. Each type shows telltale signs when it’s failing: hesitation or wobble, hair accumulation around the seal, or a stopper that won’t sit flush. When you inspect under the sink, look for a metal rod, a small Cotter pin, washers, and a rubber seal around the stopper body. If you see rust or cracked rubber, replacement parts will likely be needed. Identification is critical to choose the right tools and steps for disassembly and reassembly.

Safety and Prep Before You Start

Before you touch any drain hardware, prep is essential. Clear the area around the sink, lay down a towel, and have a bucket ready for water and debris. Use protective gloves to minimize contact with grime and hair. Ensure you have good lighting; a small flashlight helps locate the linkage and any hidden screws. If you’re working in a kitchen, consider turning off the disposal unit or unplugging nearby appliances for safety. Keep all screws and small parts in a labeled container so you don’t lose them. Finally, check a local code or manufacturer guidance to confirm you’re using the correct parts for your sink model.

Diagnose Before Disassembly: What You’re Dealing With

Start by observing whether water drains slowly when the stopper is open versus closed. A healthy drain should evacuate quickly when open and seal properly when closed. If water drains slowly in both states, the issue may be mineral buildup in the trap or a clog beyond the stopper. If the stopper doesn’t seal even when fully closed, inspect the seal surface for nicks, cracks, or mineral buildup that prevents a tight seal. Listen for clicking or wobbling noises when you operate the linkage—the sound can indicate a loose pivot rod or a worn washer. Taking careful notes of symptoms helps you choose between a simple cleaning, a part replacement, or a full reassembly.

Comprehensive Fix Walkthrough: Step-by-Step Overview

This section provides an overview of the fix approach rather than a verbatim how-to. Start by identifying the stopper type, then remove any screws or caps that secure the linkage. Clean the stopper, seal, and drain area thoroughly to remove hair and soap scum. Inspect washers and o-rings for wear and replace as needed. Reassemble the linked components, then test the stopper in several cycles to ensure a snug seal without binding. If the mechanism remains stiff, adjust the linkage length or pivot arm angle according to the manufacturer’s guidance. Finally, perform a quick maintenance routine to prevent future clogs.

Drain Guide emphasizes that staying organized and taking photographs during disassembly can help you reassemble accurately. When in doubt, replace worn components with compatible parts and avoid forcing components that appear stuck. This reduces the risk of damaging the drain or creating leaks.

Preventive Maintenance and When to Call a Pro

Regular maintenance can prevent most stopper issues. Clean the drain and stopper monthly, remove debris after shaving or applying body oils, and check for wear on gaskets and washers every six months. If you encounter persistent leaks, corrosion, or a stopper that won’t disengage, it’s wise to consult a licensed plumber. In some cases, the backing rod or pivot linkage may be seized beyond simple cleaning and require professional service. Drain Guide recommends maintaining a simple repair kit with spare washers and seals so you can address minor wear before it escalates.

Tools & Materials

- Bucket or bowl(To catch water and debris)

- Flashlight(For visibility under the sink)

- Adjustable wrench(For loosening tight nuts or collars)

- Screwdrivers (Phillips and flathead)(For screws on stopper cap and linkage)

- Pliers (needle-nose preferred)(To grip small parts and remove linkage)

- Rag or towels(Keep area clean and dry)

- Plastic container or magnetic tray(Store small parts to avoid loss)

- Replacement seals/washers (optional)(Have on hand if wear is evident)

- Drain snake (optional)(For deeper clogs beyond stopper)

- White vinegar and baking soda(Gentle cleaning and deodorizing agents)

Steps

Estimated time: 45-60 minutes

- 1

Identify stopper type

Examine the stopper to determine which design you have: lift-and-turn, pop-up, toe-tap, or plunger. Understanding the type guides your disassembly and tool choice, helping you avoid unnecessary damage.

Tip: Take a quick photo of the linkage before you touch it to help with reassembly. - 2

Access the linkage

Clear the area under the sink and locate the lift rod, pull rod, or central post. Remove any decorative cap or cover so you can access the screws or nuts that secure the linkage.

Tip: If there’s stubborn grime, spray a small amount of penetrating oil and wait a few minutes. - 3

Disconnect and remove the stopper

Carefully detach the linkage from the stopper, noting how parts connect. Remove the stopper body from the drain if needed to inspect the seal and check for hair and buildup.

Tip: Keep track of all small components in a labeled container. - 4

Clean and inspect

Thoroughly clean the stopper, seal, and the drain opening. Remove hair, soap scum, and mineral deposits. Inspect washers and seals for cracks or wear; replace if necessary.

Tip: Use a soft brush and mild cleaner to avoid scratching rubber parts. - 5

Replace worn parts

If you find a cracked seal, bent linkage, or a worn washer, replace with exact-fit parts. Recheck compatibility with your sink model before purchasing.

Tip: Avoid cheap, incompatible parts that could cause leaks. - 6

Reassemble the stopper

Reinstall the stopper and linkage in the reverse order of removal. Ensure the seal sits flush and that the linkage moves freely without binding.

Tip: Hand-tighten nuts first, then snug with a wrench to avoid over-tightening. - 7

Test operation

Run water and test several cycles: open, close, and hold for a moment to check the seal. Look for drips around the drain and verify it drains smoothly when open.

Tip: If the stopper sits high or low, adjust the linkage length slightly and test again. - 8

Clean up and document

Wipe surfaces dry, return tools to the toolbox, and note any parts replaced. A quick maintenance routine can prevent future issues.

Tip: Keep spare washers in a labeled bag for next time.

Got Questions?

What stopper types are most common in residential sinks?

The most common types are lift-and-turn, pop-up, toe-tap, and plunger stoppers. Each type has different linkage and seal components, so identification helps you pick the right approach and tools.

Common residential stoppers include lift-and-turn, pop-up, toe-tap, and plunger types. Identifying the type guides the correct disassembly and parts replacement.

Do I need to remove the entire drain assembly to fix a stopper?

Usually you don’t need to remove the entire drain. You can access most linkages from under the sink and remove the stopper assembly through the drain if necessary. Only remove the whole drain if there’s corrosion or extensive damage.

Most fixes don’t require removing the entire drain, just the stopper linkage and seal. Only remove the whole drain if you see corrosion or serious damage.

Can chemical drain cleaners help with a stopper issue?

Chemical cleaners can help with surface buildup but are not a fix for mechanical wear or broken seals. Use chemicals cautiously and follow safety guidelines; they won’t repair a damaged stopper.

Chemical cleaners may help minor buildup, but they won’t fix damaged seals or broken linkages. Use them sparingly and safely.

How long does a typical stopper repair take?

A straightforward stopper fix typically takes 30 to 60 minutes, depending on stopper type and accessibility. Allow extra time for parts replacement if needed.

Most fixes take about half an hour to an hour, depending on the model and access.

What if the stopper is corroded or irreparably damaged?

If corrosion or severe wear is evident, replacing the stopper or the whole linkage is usually best. Choose a compatible kit designed for your sink model.

If corrosion is apparent, replacing the stopper assembly is often the best choice.

Should I lubricate the pivot rod or linkage?

Light lubrication on metal pivots can help with movement, but avoid over-lubricating rubber seals. Use a silicone-based lubricant if needed and compatible with plastics.

A little silicone-based lubricant on metal pivots can improve movement; avoid rubber seals.

Watch Video

The Essentials

- Identify stopper type before disassembly.

- Clean hair and mineral buildup for reliable sealing.

- Inspect seals and replace worn parts as needed.

- Test thoroughly and maintain regularly.