How to Remove Sink Drain: Step-by-Step Guide

Learn how to safely remove a sink drain with a clear, step-by-step method. This Drain Guide guide covers tools, safety, and common mistakes for DIY homeowners tackling drain removal.

You will remove a sink drain and inspect or replace components as needed, then reseal the system to restore proper drainage. You’ll need basic tools (adjustable wrench, pliers, bucket) and a few towels. This guide walks you through disconnecting the drain, loosening slip nuts, lifting the drain assembly, and inspecting the P-trap for wear or damage. Expect some splash—have towels ready and note sealant compatibility. After removal, decide whether to replace with a new drain or repair the tailpiece as necessary.

Overview: what you’re doing when you remove a sink drain

Removing a sink drain is a common DIY task that helps clear clogs, replace damaged parts, or upgrade to a better seal. When you perform this task, you’ll detach the drain from the sink and access the tailpiece and P-trap below. With the right steps, you can prevent leaks and leaks from forming after reinstallation. In this guide, you’ll learn to identify parts, gather tools, and follow a safe sequence to remove the drain using reasonable care. The keyword how to remove sink drain should appear in this passage to reinforce search relevance.

Anatomy of a sink drain

A typical sink drain assembly consists of a strainer or flange at the sink surface, a tailpiece that extends downward, a P-trap that curves beneath, and slip nuts that hold components together. Understanding how these parts fit helps you anticipate what you’ll disconnect, what may be removable, and where to check for wear. Most residential drains use standard sizes, so compatible replacement parts are easy to source. If you’re upgrading, you’ll want to measure diameter, tailpiece length, and trap size before shopping.

Safety first: hazards to watch for

Drain work can involve sharp edges, water exposure, and potential exposure to sewer gases. Always shut off the water supply, drain any standing water, and ventilate the area. Wear gloves and eye protection, use a bucket to catch splashes, and avoid forcing fittings which can crack or strip threads. If you encounter stubborn corrosion, apply penetrating oil and pause to let it soak as needed before attempting to loosen fittings.

Tools and materials at a glance

Before you begin, confirm you have the essential tools and replacement parts. While you’ll find a full list in the Tools & Materials section, this quick glance helps you stay organized. A standard adjustable wrench, channel-lock pliers, basin wrench for tight spots, a bucket to catch water, old towels for spills, and plumber’s tape or thread sealant are typically enough for most removals. If you’re replacing a drain, have a compatible replacement kit on hand.

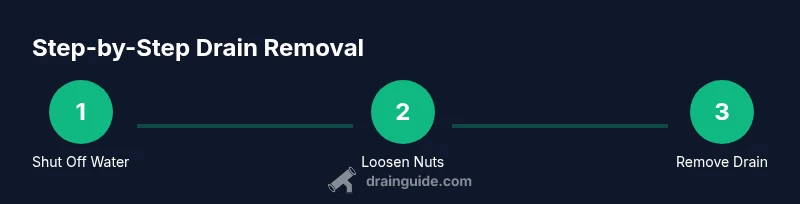

High-level step-by-step overview of the removal process

The removal process generally follows a familiar sequence: (1) prepare the workspace and turn off water; (2) loosen the slip nuts and capture water with a bucket; (3) disconnect the drain flange from the sink and remove the drain body from underneath; (4) inspect the P-trap and tailpiece for wear or damage; (5) clean threads and install the new or reused drain assembly; (6) reassemble, tighten connections, and test for leaks. The goal is a clean, leak-free seal that lasts.

Common issues when removing a sink drain

Common issues include stubborn nuts that strip, a corroded P-trap, or fittings that won’t loosen without twisting pipes. Leaks often appear after reassembly if threads aren’t clean or the gasket is damaged. Plan for extra time if you have hard water buildup or if you’re working with an older home where metal corroded over years. Patience and proper technique will improve outcomes.

Reinstallation options and leak testing

After removal, you can either replace the drain with a new unit or reset the existing hardware after replacing worn gaskets and seals. Re-torque slip nuts gradually in a cross pattern to avoid warping. Once assembled, run water and inspect for leaks around all joints. If a leak appears, tighten further or reseal with fresh plumber’s tape where appropriate.

Maintenance to prevent future clogs

To keep drains flowing freely, consider a routine that includes hot water flushes, occasional baking soda and vinegar treatments, and careful disposal of fats and oils. Use a drain screen to catch debris and clean it regularly. Address slow drainage promptly to avoid buildup that can become a stubborn clog.

Tools & Materials

- Adjustable wrench(Fits slip nuts up to about 1-1/2 inch.)

- Channel-lock pliers(Useful for stubborn fittings.)

- Basin wrench(Helpful for tight spots under the sink.)

- Bucket(Catch water and spills.)

- Old towels or rags(Protect cabinet and absorb spills.)

- Replacement drain assembly or parts kit(Have spare gasket and washers on hand.)

- Plumber’s tape (PTFE tape)(Seal threaded connections.)

- Penetrating oil(Loosen corroded nuts; let soak.)

- Flathead screwdriver(Can aid in prying or loosening.)

- Rags and trash bag(Contain waste and keep area tidy.)

Steps

Estimated time: 60-90 minutes

- 1

Shut off water and prepare workspace

Locate the shut-off valves under the sink and turn them clockwise to stop water flow. Place a bucket beneath the drain and lay towels around the area. This step prevents spills and protects cabinets while you work.

Tip: Check both hot and cold valves if present; some fixtures share a common shut-off line. - 2

Loosen slip nuts and position a catch

Use an adjustable wrench to loosen the slip nuts on the P-trap and drain assembly. Keep the bucket underneath to catch water remaining in the trap. Do not remove all nuts at once if you feel resistance.

Tip: Loosen nuts a little at first to avoid sudden water gushes. - 3

Disconnect the drain flange from the sink

From above the sink, remove the drain flange or nut that holds the strainer in place. If the nut is hard to reach, use a basin wrench or pliers carefully to avoid scratching finishes.

Tip: Wear gloves to protect your hands from sharp edges. - 4

Remove the drain body from underneath

With the assembly loosened, lower the drain body from beneath the cabinet. Slide the unit down and away, keeping an eye on the gasket and washers so they don’t drop.

Tip: Take a photo of the setup before removal; it helps during reassembly. - 5

Inspect the P-trap and tailpiece

Look for rust, cracks, or heavy mineral buildup. If the pipe shows wear or leaks, plan to replace the affected components. Clean threads and mating surfaces before reassembly.

Tip: If you see a cracked gasket, replace it to prevent future leaks. - 6

Reinstall or upgrade the drain assembly

Install the new drain or reinstall the existing parts with fresh gaskets. Hand-tighten first, then snug with a wrench—do not overtighten as this can crack fittings.

Tip: Use plumber’s tape on threaded connections to improve sealing. - 7

Test for leaks and clean up

Turn the water back on and run cold water for several minutes. Check all joints for leaks; wipe away any water and ensure everything is dry before closing the cabinet.

Tip: If a leak appears, tighten a bit more and retest; otherwise replace washers or gaskets as needed.

Got Questions?

What tools do I need to remove a sink drain?

Most removals require an adjustable wrench, pliers, a bucket, towels, and a replacement drain kit or gaskets. You may also use a basin wrench for hard-to-reach fittings.

You’ll typically need a wrench, pliers, a bucket, towels, and possibly a replacement drain kit. A basin wrench helps in tight spaces.

Can I remove a sink drain without turning off the water supply?

No. Always shut off the supply to avoid water spraying when you loosen fittings. If you can’t locate the shut-offs, switch off the main water valve temporarily.

It’s not safe to remove a drain without turning off the water. Use the under-sink valves or the main valve if needed.

What should I do if the drain is stubborn and won’t loosen?

Apply penetrating oil to joints and let it soak for 5–10 minutes. Wedge a rubber strap wrench or use a breaker bar for extra leverage, taking care not to crack fittings.

If it’s stubborn, use penetrating oil and a little extra leverage. Let it soak first.

Is it better to replace or reuse an old drain?

If the gasket is worn, corroded, or if there are leaks, replace with a new drain assembly. Reuse is acceptable only if all parts are in good condition and seals are intact.

If seals look worn or pipes show corrosion, replace rather than reuse.

How long does removing and reinstalling a sink drain usually take?

Most DIY removals take about 60–90 minutes, depending on pipe access and the condition of fittings. Allocate extra time for stubborn parts or replacing the drain.

Plan for about an hour to an hour and a half, with extra time if parts are corroded.

What signs indicate a leak after reassembly?

Look for damp spots around joints, water dripping at seams, or a musty smell from hidden moisture. Re-tighten connections and replace worn washers if leaks persist.

If you see moisture around joints, re-tighten or replace washers and re-test.

Watch Video

The Essentials

- Turn off water and prep workspace before starting

- Inspect parts for wear; replace damaged gaskets

- Don’t overtighten joints to avoid cracking

- Test for leaks and verify a clean seal

- Maintain drains with regular cleanings to prevent clogs